PROCELL

PROCELL

PROCELL

PVC

LIGHT FOAM SHEET

|

|

|

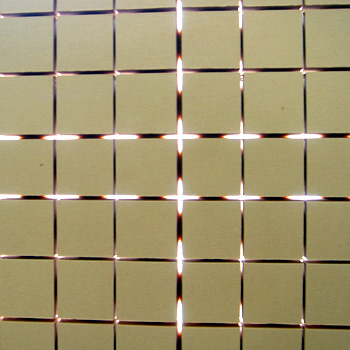

PROCELL closed cells characteristic is a unique foam technology, a polymer with high tensile strength, light weight and great hardness. PROCELL is anti-chemical, low density, tough without break, thermoplastic, good anti-stress and shear strength. PROCELL is suitable for handiwork multi-layers, fitting, sandwich and vacuumed forming panels, which is definitely best core materials for the sandwich panels and a replacement of wooden core materials.

PROWANG insists to use high quality materials that are harmless to human bodies. Our PVC PROCELL is qualified to RoHS standard test and does not contain formaldehyde, heavy metals, DOP and TVOC. Customers may feel ease to use and recycle our panels. We are capable of satisfying various market requirements with our high quality materials, flexible design and competitive cost.

Standard Size:

|

Panels Thickness (mm) |

Panels Length (mm) |

|

1220mm |

2440mm |

|

1220mm |

1220mm |

|

Thickness

Capability: 6mm to 50mm |

|

|

Density

Range: 80kg/ m3 to 250kg/m3 |

|

Panels Applications:

- Building partition or decoration for dwellings, offices, public places or boats etc.

- System furniture, kitchen cabinets, bathroom cabinets, living room cabinets and shoes cabinets.

- Furniture of all kinds of desks, closets or bedsides cupboards etc.

- Cubicle boards, showcase boards, cabinet boards and partition boards.

- Floor boards of cars, buses, trains or yachts.

- Sign boards of advertising, exhibitions, computer printing or window shopping decoration.

- Modem interior-exterior architecture design.

- Door planks for bathrooms, washrooms or resting rooms.

- Floor boards for bathrooms, washrooms, rest rooms and interior design.

- Interior, exterior boards and DIY furniture.

- Waterproof, moisture proof and weather durable facilities boards.

- Fire prevention, flame resistant facilities boards.

Panels Characteristics:

1. Without wood natural defective problem, such as chap, bend, or rot problem and no need for maintenance constantly.

2. Waterproof, moisture proof, mildew proof, corrosion resistant and

moisture durable.

Solve the wood problem which is easily rotted, expanded and deformed because of

moisture or vapors.

3. Self-fire extinguishing and non combustion-supporting features.

Certification of

USA UL94 V - 0 Flammability standard and CNS7614 Class I fire code requirement.

4. Environmental-friendly green healthy materials, negative content of heavy metals, formaldehyde, TVOC and asbestos. Qualification of RoHS safety standard.

5. Plastics features of well storage for long periods of time, hardly deformed

and

long time usage.

6. Lightweight quality, good core materials for sandwich construct.

7. Good anti-chemical properties, acid proof and bear the alkali.

8. Good dimension stability and able to reprocess again and again.

9. Weather resistant and able to set outdoor over a period of time.

10. High Insulation.

11. Anti-insects and anti-termites.

12. Suitable for printing and fitting process.

13. Light weight and Toughness features.

14. Certification of ISO 9001: 2008.

SGS Test Reports: