Thermal Mold Insulation Board

Thermal Mold Insulation Board

Thermal

Mold

Insulation

Board

A. Ingredients and

processing technology

Using high temperature and high pressure

molding technology, strictly select best

heat resist and 2500MT high

pressure resist resins and enhanced glass fiber

materials.

B. Advantages and

characteristics

1.

Use harmless substances to

the human bodies, no asbestos contents.

2.

Excellent high

temperature and chemical resistance, oil and water resistance.

3.

High-performance

compression and bending strength, no cracks and no collapse.

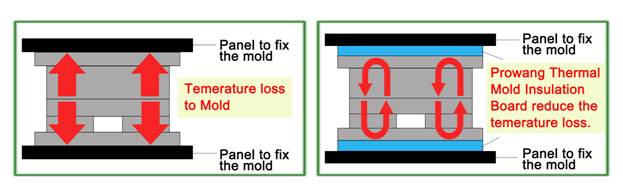

4.

Low thermal conductivity,

better heat insulation, quick heat increasing quality to shorten the heating

time, precisely mold temperature control.

5.

Environmental protection,

reduce temperature loss and save electricity costs.

6.

Long life service, save time

to replace materials, enhances productivity and save maintenance costs.

C. Processing methods

Mold-specific insulation boards can

be cut and machined using common metal

tools and diamond

cutting tools.

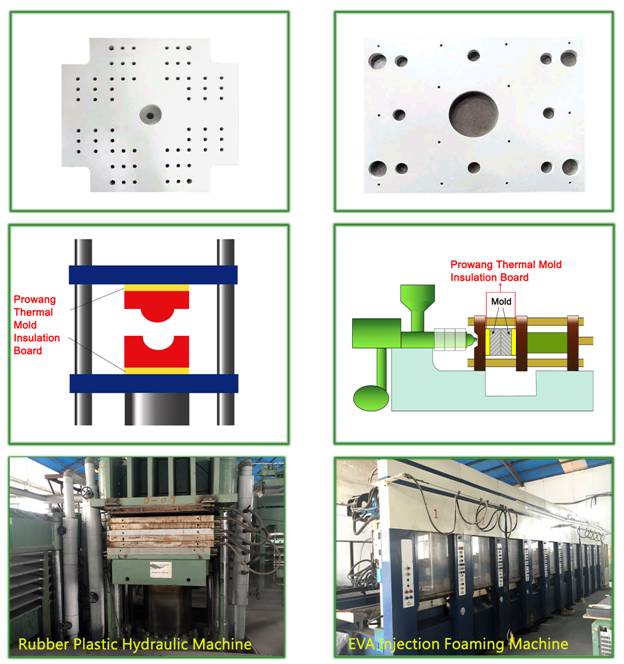

D. Application

Widely used in hydraulic

man-made board, injection machine, hydraulic machine,

rubber / tire curing

machine, plastic molding mold, tool and mold manufacturing.

E. Physical performance

|

Test

Items |

Procedure |

English

Units |

Typical Values |

Metric

Units |

Typical

Values |

|

Specific Gravity |

ASTM D 792 |

lbs/ft3 |

123 |

g/cm3 |

1.97 |

|

Water Absorption |

ASTM D 570 |

% by wt. |

0.02 |

% by wt. |

0.02 |

|

Continuous Use Temp. |

Prowang |

F |

392 |

C |

200 |

|

Maximum Service Temp. |

Prowang |

F |

482 |

C |

250 |

|

Flexural Strength |

ASTM D 790 |

Psi |

66006 |

Mpa |

455 |

|

Compressive Strength |

|

||||

|

@ 75oF / 24oC |

ASTM D 695 |

Psi |

56411 |

Mpa |

389 |

|

@302oF / 150oC |

ASTM D 695 |

Psi |

47964 |

Mpa |

331 |

|

@392oF / 200oC |

ASTM D 695 |

Psi |

45760 |

Mpa |

307 |

|

Compressive Modulus |

ASTM D 695 |

Psi |

3569845 |

Mpa |

24619 |

|

IZOD Impact Strength |

ASTM D 256 |

Ft.lb/in |

9.2 |

J/cm |

4.8 |

|

UL Subject 94 |

UL-94 |

HB |

Pass |

HB |

Pass |

|

Thermal Conductivity |

ASTM C 177 |

BTU.in/Hr.Ft.F |

1.8 |

W/m.K |

0.26 |

|

Coefficient of Thermal

Expansion Across Thickness |

ASTM D 696 |

In/In/C x 10 |

|

10/K |

32.81 x 10-6 |

F. Standard size:

![]() Width 1220mm x length

2440mm Thickness: 5, 8,

10, 12, 15, 19, 25mm

Width 1220mm x length

2440mm Thickness: 5, 8,

10, 12, 15, 19, 25mm

![]() Accept designated cutting

or CNC cutting.

Accept designated cutting

or CNC cutting.

G. Inspection and

packaging

![]() After mass production, test

each batch 200 degrees Celsius, clamping million times

After mass production, test

each batch 200 degrees Celsius, clamping million times

150kg /cm2 (1500 tons),

shipment and package when test qualified.

![]() Carton / pallet packing.

Carton / pallet packing.